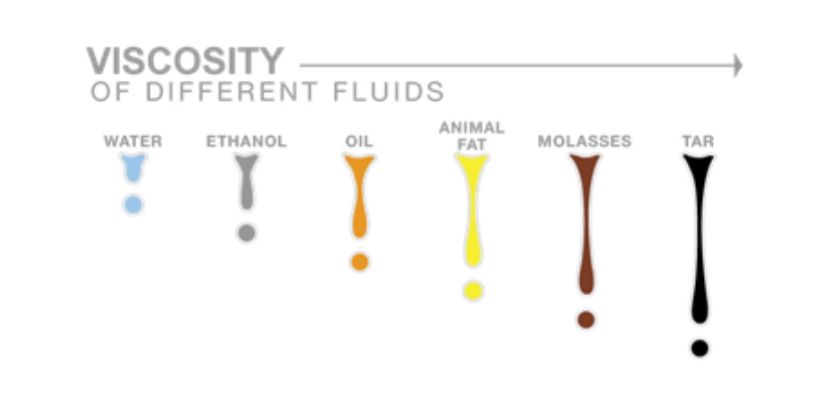

Understanding the types of viscosity

Viscosity is the measure of a fluid’s resistance to flow, and it can vary significantly from one substance to another. Understanding viscosity is crucial as it directly impacts the need for heating in different applications. Let’s break it down:

Low Viscosity Fluids

Fluids with low viscosity, such as water or thin oils, flow effortlessly and offer minimal resistance to movement. These substances typically do not require heating for most applications, as they are naturally suited for use at room temperature.

Medium Viscosity Fluids

Medium-viscosity fluids, like thicker oils, syrups, resins, and some oils and greases, exhibit moderate resistance to flow. The need for heating in these cases depends on the specific application. Some products, like syrups and greases, may require heating to reduce their viscosity for easier pouring or mixing.

High Viscosity Fluids

Highly viscous fluids, such as molasses, honey, palm oils, surfactants, and industrial greases, present significant resistance to flow. These substances often necessitate heating to lower their viscosity, making them more manageable. The application of heat reduces their thickness, allowing for easier pumping, pouring, or processing.

The link between temperature and viscosity

The reason for heating is primarily to reduce viscosity in higher-viscosity fluids. The increase in temperature provides additional kinetic energy to the fluid’s molecules, causing them to move more freely and thereby reducing the resistance to flow. This is especially important in industrial processes, where highly viscous materials need to be transported, mixed, or processed efficiently.

Tailoring industrial heating solutions for varying viscosity needs

In general, medium-viscosity products may only require heating during the winter months when lower ambient temperatures tighten fluid molecules. For such cases, our HHD insulated heater jackets (Hi-Heat range) for drums, grease, and Intermediate Bulk Containers (IBC) heating jacket provides an ideal solution.

On the other hand, high-viscosity products demand consistent heating throughout the year to lower resistance to flow. For these scenarios, our Hi-Power range of drum heaters, sometimes combined with base heaters, or our IBC3 heater jacket, possibly paired with an IBC immersion heater, emerge as the best options.

Key Insights on reducing the viscosity of liquids

- Viscosity is about how thick or runny your product is. It is generally measured in Centipoise (cps) or Centistokes (cSt).

- In general Newtonian (eg. oils) and Thixotropic products (eg. honey, paint) react well to the application of heat to reduce viscosity.

- Consider using heating products such as insulated heater jackets, immersion heaters, induction heaters and drum base heaters to reduce viscosity efficiently.

- For medium viscosity try our Hi-Heat specification jackets.

- For high viscosity try our Hi-Power specification jackets sometimes in combination with an immersion heater or drum base heater.

- Always consider the pump you are using in conjunction with the heating equipment – particularly with viscous products, heating alone will not be the sole answer. You may need a positive displacement pump.

- You should also consider whether you need a mixer/agitator to aid with creating flow, in conjunction with your pump and / or heater.

-

Efficient industrial heating solutions by SBH Solutions

SBH Solutions provides a range of efficient heating products designed to reduce viscosity, whether this be in a small or larger container, whether this be in a normal safe or a hazardous environment, or whether it be an inside or outdoor location. Talk to us about our range of heating products so that we can help you select correctly and you can have one less problem to worry about.